Now hiring | Multiple roles

View active rolesNow hiring | Multiple roles

View active roles

The mining industry places a strong emphasis on safety, recognizing the inherent risks involved in mining operations. One of the crucial aspects of ensuring safe operations in open-cut mines and tailing dams is slope-stability monitoring.

.

To achieve a comprehensive understanding of slope stability and dam integrity, mine operators often rely on a combination of different monitoring technologies. These technologies include various instruments and sensors designed to measure parameters such as ground movement, deformation, stress, and water levels. Each technology provides specific data points, and when combined, they offer a holistic view of the situation.

In this context, Sixense provides a full range of monitoring instruments and technologies tailored to the mining industry. These instruments are designed for diverse applications and can be deployed in different areas of a mine or tailing dam. They are equipped with wireless dataloggers that collect in real-time data on critical parameters related to slope stability and dam integrity.

.

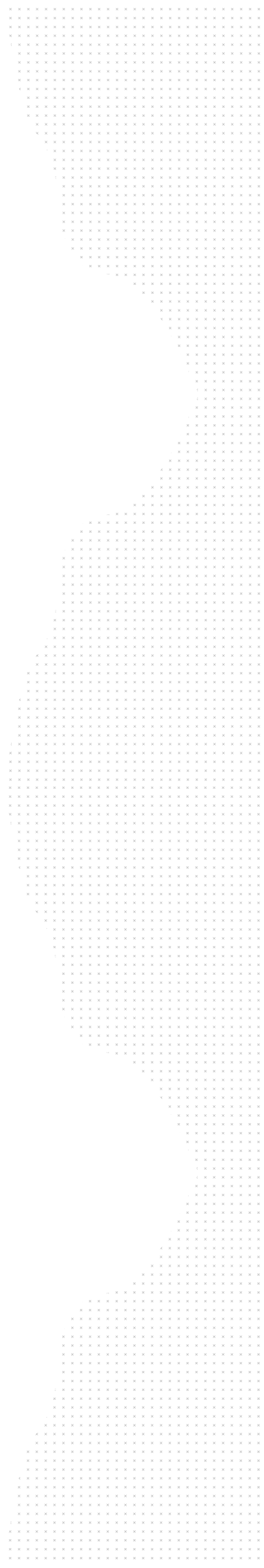

In addition to the monitoring instruments, we offer software packages that integrate all the collected data into a single platform: Beyond Monitoring. This integrated package serves as a central hub for data management and analysis. It enables mine operators to quickly gather and visualize data, allowing them to gain insights into the current conditions of slopes and tailing dams.

.

One of the key advantages of our integrated package is the inclusion of advanced quality control (QC) procedures. These procedures ensure that the collected data is accurate and reliable, minimizing the chances of false alarms or missed warning signs.

.

By offering a comprehensive solution that combines monitoring instruments, data integration, advanced QC procedures, and workflow management, Sixense aims to enhance safety in mining operations. We provide mine operators with the tools and services necessary to proactively monitor slope stability and dam integrity, enabling them to make informed decisions and respond effectively to potential risks or hazards.

We only integrate sensors that we have evaluated, selected, tested and that we are regularly benchmarking. We work with all of the main instrument suppliers and are agnostic in terms of technology, protocol and formats.

We install the sensors on site, with qualified and trained staff, in accordance with high quality and safety standards.

Alternatively, we integrate data from your existing instrumentation system into our single data hub, Beyond Monitoring, so that all data can be visible together, enabling cross-comparison for advanced insights.

Jwaneng Mine is the flagship of the Debswana Diamond Company in Botswana. The mine became fully operational in August 1982 and there is an ongoing program to reach 624 metres. This operation is supported by a far-reaching instrumentation and monitoring network.

Instrumentation is provided by different vendors and Sixense has integrated all data in Geoscope allowing for cross-correlation of data types to enhance data insights and sytem reliability.

Slope stability radar

Types of different instrumentation

Measurements per day

Hydrological Sensors

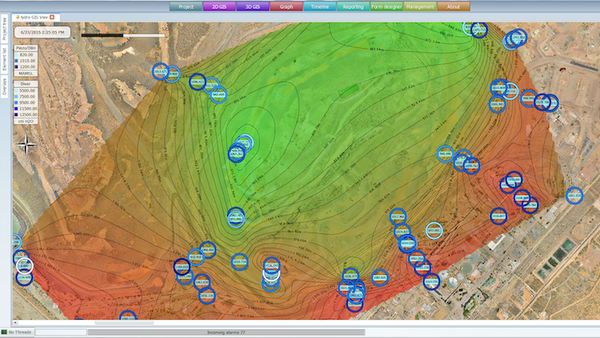

Sixense has implemented an integrated asset management and instrumentation monitoring system at Goro mine using Gescope and Beyond Asset.

Geoscope is used as a central data hub for instrumentation data, including geotechnical sensors, hydrological and weather data, and survey settlement data.

Beyond Asset is used to plan and conduct maintenance and inspection tasks, and is also used by field technicians to collect manual instrumentation data.

Beyond Asset and Geoscope databases are connected to seamlessly transfer data between the two.

Extensometers / Inclinometers

VW Piezometers

Survey / Settlement Monuments

Hydrological Sensors

The Phu Kham Copper-Gold Operation, the flagship project of PanAust Limited, is situated within the Phu Bia Mining Contract Area in Laos, approximately 140 kilometres north of the capital city, Vientiane.

In close proximity, about 25 kilometres to the west, lies the Ban Houayxai Gold-Silver Operation. Since 2012, Ban Houayxai has been operating an open-pit mine, feeding ore to a carbon-in-leach recovery process plant with a capacity of four million tonnes. Both mines feature dedicated tailings storage dams, ensuring efficient and safe waste management.

To support these operations, Sixense Oceania has deployed Beyond Monitoring to integrate and manage extensive survey and geotechnical data in real time, providing alarms and customised dashboards. This robust system handles the large volume of sensors across both mine sites and tailings storage facilities, adapting seamlessly to daily operational changes and developments.

3D Prisms

VW Piezometers & Standpipes

Weather Stations

Manual Inclinometer

The Eloise Copper Mine project, located in Queensland, Australia, involves the extraction of copper and gold through both open-pit and underground mining methods. The operation uses advanced technologies and modern infrastructure to efficiently access and manage the mineral resources. By focusing on resource optimisation, the project contributes to the global supply of copper and gold.

In collaboration with ConeTec, Sixense Oceania has supplied and installed piezometers and dataloggers, powered by a solar gateway, for the Eloise Copper Mine tailings dam. All data is reported in real-time to Beyond, with real-time alarms and automated reporting to ensure continuous monitoring and prompt response.

WV Piezometers

WV Data Loggers

Gateway

Koniambo Nickel is a major mining and metallurgical complex located in the Northern Province of New Caledonia. The company is a joint venture between Société Minière du Sud Pacifique (SMSP), a New Caledonian mining company and Glencore.

Sixense has implemented a secure and proprietary data transmission framework around the site. Sixense's Monitoring & Information Management System (MIMS), Beyond Monitoring, collects and displays the data, triggers alarms, and generates reports. The automation of the monitoring network has provided significant benefits in terms of situation awareness.

Vibrating Wire Piezometer

Wireless dataloggers

In Place Inclinometer

Beyond Monitoring users