Now hiring | Multiple roles

View active rolesNow hiring | Multiple roles

View active roles

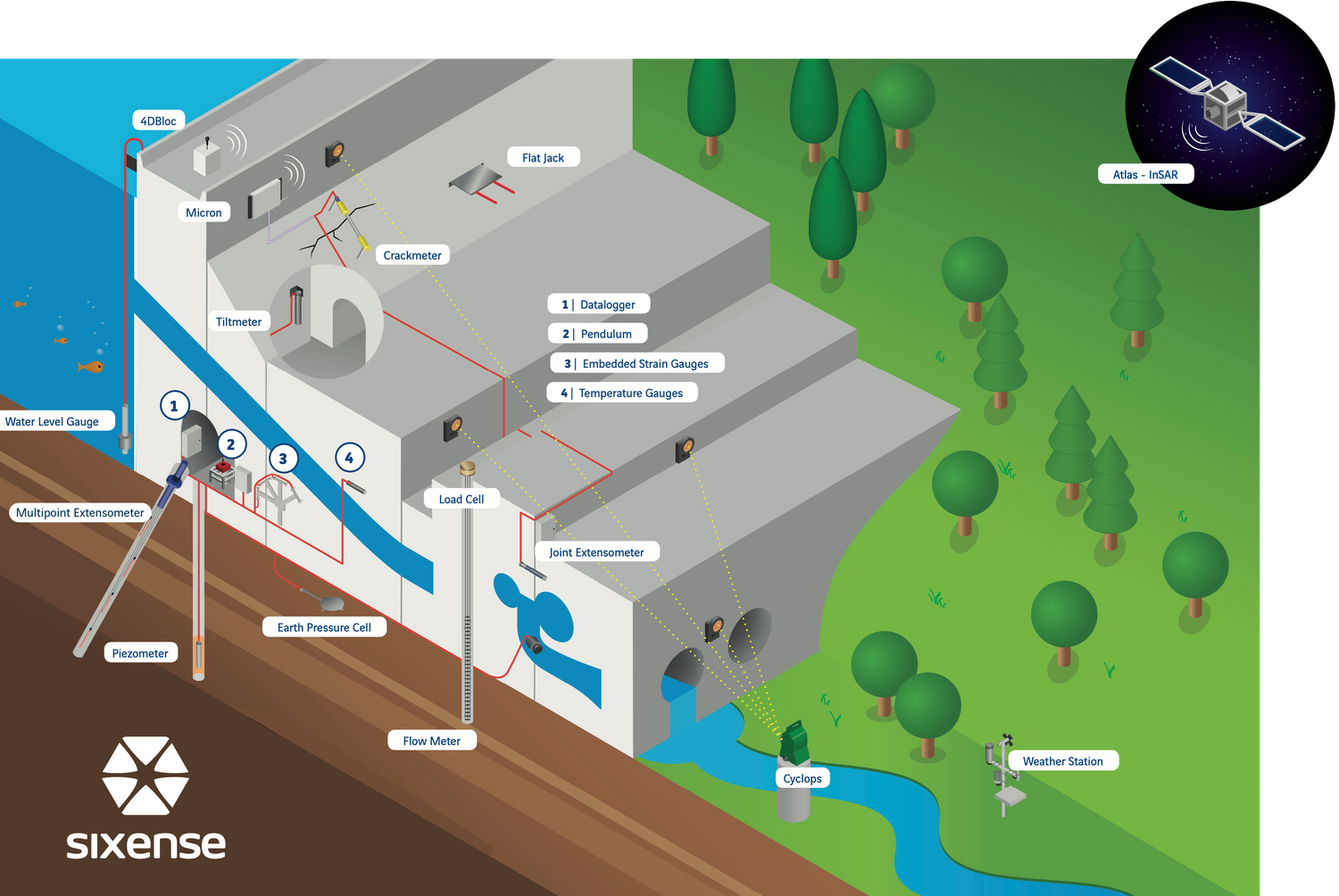

Dam safety is primarily based on robust design and construction. Monitoring the structure allows to verify the short or long term behaviour is what is expected or if unforeseen phenomena need to be further investigated. The monitoring system depends on the type of dam, its dimensions, its age, the method of construction, as well as the specific conditions of the site, in particular those related to the foundations.

We've been implementing automatic monitoring systems for tailings, embankment and concrete dams, including their foundations for more than 20 years.

Our services also extend to inspection, testing of concrete structures, soil characterisation, leak detection, digital model & numerical simulation.

Services can be as simple as replacing or upgrading existing instrumentation or to providing an entirely new turn-key system.

Measured parameters include structural deformation, movement, temperature, pressure, seepage and drainage.

Data related to the surroundings of the dam, such as the weather conditions, hydrology and stability of the broader area can also be included in the monitoring system.

All data is collected in a single platform - Geoscope - for display, processing and reporting. The platform includes advanced processing capabilities like the Hydrostatic, Seasonal, Time displacement (HST) model for greater insights.

Originally constructed in the 1970s and upgraded in the 1980s, Ross River Dam is essential for flood control and water management in Townsville. To ensure the long-term integrity of the dam's spillway, the Townsville City Council has initiated the installation of an automated electronic system to monitor movement and identify early signs of structural issues.

Sixense Oceania developed a cost-effective monitoring system for Townsville’s embankment, delivering reliable, high-frequency data coverage across the entire area. Integrated with the Beyond Monitoring platform, this solution provides Townsville City Council with real-time insights into dam conditions, improving the ability to assess and understand the dam's long-term health and stability.

By digitising the original hydraulic piezometers, this system enables the first automated, real-time data collection, offering a significant upgrade over previous systems with limited data frequency and reach. This modernisation offers essential tools for proactive management, particularly during extreme weather events.

WV Piezometers

Hydraulic Piezometers with VW Transducers

Crackmeters for Spillway Deflection

Turbidity Sensor and Weir System

Melbourne Water Corporation requires the construction of safety upgrades to the Upper Yarra Dam to reduce the dam safety risk of the storage facility to acceptable levels.

Sixense are designing, procuring and installing a range of instrumentation to support the dam safety upgrade works. This includes:

- Existing instrumentation which is located, protected and reinstated with upgraded datalogging systems

- New instrumentation to provide additional monitoring capabilities within the dam wall and it's surrounds

Inclinometers

Extensometers

Groundwater piezometers

Weir monitors

Cressbrook Dam is a crucial component of Queensland's flood control system, protecting local communities from extreme weather and supplying water to nearby areas. Built in 1983, the dam is undergoing major upgrades to meet the Queensland Dam Safety Management Guideline 2020, including raising the crest height and widening the spillway for better flood resilience.

Due to the dam's remote location and limited power infrastructure, Sixense Oceania implemented a solar-powered, low-maintenance groundwater monitoring system. Featuring VW piezometers and wireless dataloggers, the system continuously delivers real-time data and integrates seamlessly with the Beyond Monitoring platform.

WV Piezometers

Wireless Dataloggers

Solar-Powered Gateway

The Eraring Power Plant in New South Wales, Australia is a notable electricity generation facility that plays a crucial role in the country's energy supply. It includes a tailing dam specifically designed to securely retain the ash by-product generated on-site.

During the dam reinforcement phase, Sixense focused on achieving real-time and precise monitoring of soil behaviour. The focus was on tracking horizontal and vertical soil movements, embankment settlement, and water pressures across multiple soil layers. Robust equipment and resilient solar power ensured consistent and accurate data collection.

In addition to ground monitoring, Sixense Oceania assumed responsibility for monitoring environmental data throughout the construction phase, aiming to minimize the project's impact on the local community and biodiversity in the area.

Cyclops + 123 Monitoring Prisms

VW Piezometers

IPI +4 Horizontal Inclinometer

Warragamba Dam, Sydney's primary water supply reservoir and Australia's largest concrete gravity dam, is among the world's most significant domestic water supply structures. Operated by WaterNSW, the dam includes an extensive internal tunnel network to monitor seepage through its 3-million-tonne concrete structure.

Sixense was engaged to upgrade the ageing weir systems within these tunnels by installing high-grade stainless steel weir plates. The project posed significant challenges, including working within confined spaces, executing complex demolition and masonry repairs, and waterproofing in hard-to-reach areas. By collaborating closely with WaterNSW, Sixense delivered a precise, safe, and tailored solution, ensuring the dam's monitoring infrastructure meets modern standards.

High-grade stainless steel weir plates

The Boadella’s reservoir is responsible for the irrigation and drinking water supply for Figueres City, in Catalonia. After intensive investigation of the dam’s monitoring system, several weaknesses were found.

SIXENSE was in charge of performing the refurbishment of the monitoring system, providing and installing new sensors, a central data acquisition system and the control software, Geoscope, for real-time data analysis and automatic reporting.

Inverted pendulum (Photo)

Hydraulic piezometer

Crackmeters

Seismic systems

The concrete dams were built in the 1940’s and needed to be updated to more current standards to withstand a 1000 year flood. In order to withstand this type of event, the design called for the installation of rock anchors into the concrete blocks in both the spillway and non-overflow zones.

To mitigate the risk of failure during the work, a real-time deformation monitoring solution using Cyclops has been installed and operated.

Cyclops

Survey prisms

for alarms & reporting